I. Spectral Characteristics

Mercury Lamps:

- Mercury lamps emit a broad spectrum of light, including ultraviolet (UV), visible light, and some infrared light.

- The primary spectral range used for UV ink curing is ultraviolet, but the additional spectra (such as visible and infrared light) produced by mercury lamps can generate heat, potentially affecting the curing effectiveness and the quality of the processed items.

LED Light Sources:

- LED light sources emit monochromatic UV light, with a narrow and pure spectral range.

- Energy is concentrated in the effective curing wavelength, resulting in high curing efficiency without generating excess heat, which helps maintain the stability of the processed items.

II. Curing Efficiency and Speed

Mercury Lamps:

- The curing efficiency of mercury lamps is influenced by various factors, including lamp power, ink type, and curing distance.

- Mercury lamps require a warm-up period to reach optimal working conditions, resulting in relatively slower curing speeds.

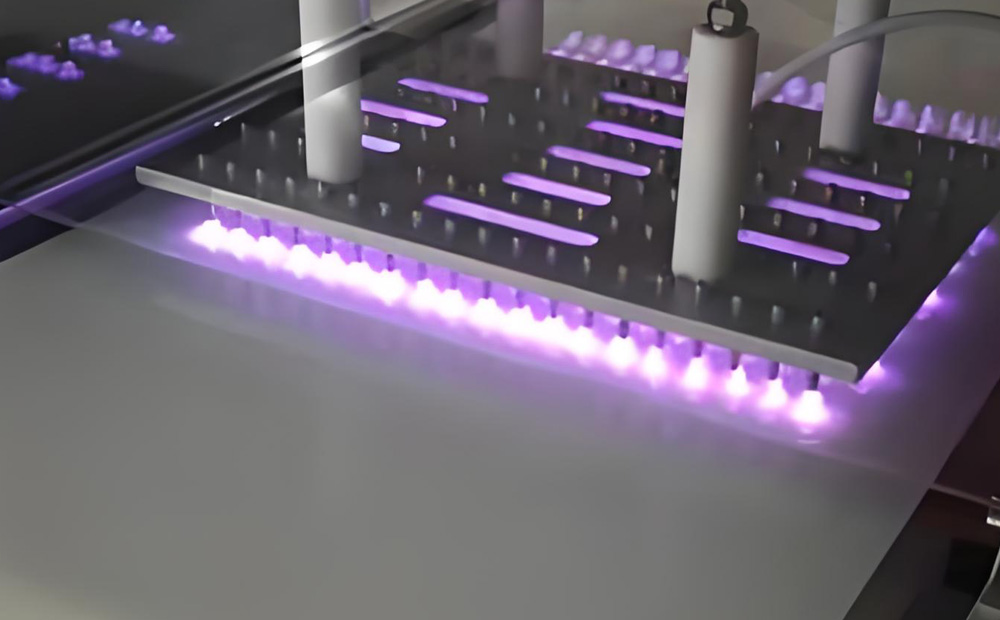

LED Light Sources:

- LED light sources have higher curing efficiency due to concentrated energy and do not require a warm-up period.

- Curing speed is faster, making them suitable for high-speed production lines and situations requiring quick curing.

III. Lifespan and Maintenance

Mercury Lamps:

- The lifespan of mercury lamps is relatively short, typically ranging from several hundred to a few thousand hours.

- Regular lamp replacements are necessary, increasing maintenance costs and downtime.

- Mercury lamps generate significant heat during operation, requiring cooling equipment to maintain lamp temperature and extend lifespan.

LED Light Sources:

- LED light sources have a longer lifespan, generally exceeding tens of thousands of hours.

- Maintenance costs are low since LED sources are less prone to damage and do not require frequent replacement.

- LED light sources generate minimal heat during operation, eliminating the need for additional cooling equipment.

IV. Environmental Impact and Safety

Mercury Lamps:

- Mercury lamps contain the heavy metal mercury, posing certain hazards to the environment and human health.

- Discarded mercury lamps require special handling, increasing disposal costs and environmental risks.

LED Light Sources:

- LED light sources do not contain heavy metals, making them environmentally friendly.

- Discarded LED light sources can be recycled, reducing environmental pollution.

- LED light sources do not emit harmful substances or gases during operation, making them safer for operators’ health.

V. Cost and Applications

Mercury Lamps:

- The initial purchase cost of mercury lamps is relatively low, but maintenance costs are high (including lamp replacements and cooling equipment maintenance).

- Mercury lamps are suitable for applications where curing speed is not critical or for traditional production lines.

LED Light Sources:

- The initial purchase cost of LED light sources may be higher, but long-term operating costs are lower (due to long lifespan, low energy consumption, and low maintenance costs).

- LED light sources are widely used in industries such as printing, electronics, furniture, and medical fields, particularly suitable for high-speed production lines and applications requiring curing precision and stability.

In summary, LED light sources have significant advantages in UV ink curing, including pure spectrum, high curing efficiency, long lifespan, low maintenance costs, and environmental safety. With ongoing technological advancements and decreasing costs, LED light sources are gradually replacing mercury lamps as the mainstream curing source for UV inks.

Leave a comment